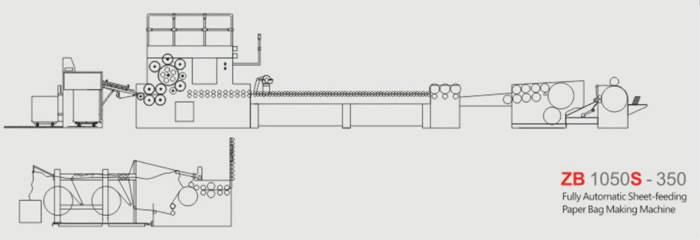

The ZB1080S-430 fully automatic paper bag making machine uses sheet-fed paper, reel reinforced paper and paper twist rope as starting materials. During the course of paper bag forming, two types of non-stop processes i.e. handle making, handle sticking, top folding, tube forming, gusset folding, bottom sealing, compacting and output, or reinforced paper sticking, top folding, tube forming, gusset folding, eyelets punching, bottom pasting, compacting and output can be perfectly completed by this paper bag forming machinery at a stroke.

This paper bag manufacture machine is especially fitted for manufacture of different ranges of hand paper bags for packing of clothing, footwear, sport brand goods or luxury brand goods. The whole production process is truly automated, and the finished bags can be directly packaged to the customer without any other treatment.

Configurations and Features

1. The automatic paper bag making machine is equipped with a handle feeding unit which features advanced machine design concept, mechanical automatic tension control, and automatic handle position adjustment.

2. Enhanced pre-stack paper feeder is capable of implementing non-stop feeding, thus considerably saving paper loading and adjustment time.

3. The paper bag machine is outfitted with a handle forming unit. This unit comes with hyperbolic rocker mechanism, Nordson hot melt adhesive gluer which can control glue length and position, and automatic slitter.

4. The reinforced paper gluing unit is available with both manual and automatic options which are controlled by central computer to ensure uniform gluing and unified quality to each bag.

5. This type of sheet-feeding paper bag making machine is designed with an automatic creasing and eyelets punching unit which can carry out automatic creasing and punching together.

6. Delicately designed front and side guides can accurately position every sheet-fed paper so as to ensure the uniformity of every batch of bags.

7. Our product comes with an opening edge cutting unit which can control the position of notching to lay a great foundation for handle pasting.

8. The top folding unit is controlled by mechanical multi-cam structure which contributes to enormous improvement of production efficiency.

9. An automatic edge gluing unit with patented technology is adopted. It can implement automatic gluing, keeping uniformity and stability.

10. This fully automatic sheet-feeding paper bag making machine boasts an automatic bag collection unit which can carry out automatic counting, hence convenient for bag collecting.

| |

|||

| Max. sheet size (LX W) | 1080×600 | 1080×600 | 1080×600 |

| Min. sheet size (LX W) | 600×350 | 600×350 | 600×320 |

| Paper Weight | 90g-230g | 90g-250g | 90g-230g |

| Bag Width | 220-430mm | 200-430mm | 220-430mm |

| Bottom Width | 80-180mm | 80-180mm | 80-180mm |

| Bag Length | 250-490mm | 250-490mm | 260-540mm |

| Top Folding Width | 40-60mm | 40-60mm | - |

| Handle Patch Length | 188.5mm | 188.5mm | 188.5mm |

| Handle Patch Width | 35-55mm | 35-55mm | 35-55mm |

| Handle Patch Weight | 100g-300g | 100g-300g | 100g-300g |

| Handle Patch Roll Diameter | Ф1200mm | Ф1200mm | Ф1200mm |

| Handle Patch Roll Width | 70-110mm | 70-110mm | 70-110mm |

| Paper Rope Diameter | 4-6mm | - | 4-6mm |

| Paper Rope Height | 170-195mm | - | 170-195mm |

| Speed | 50-80bags/min | 50-80bags/min | 50-80bags/min |

| Total power | 15kw | 15kw | 15kw |

| Total Weight | 20T | 20T | 20T |

| Machine size | 16100×5100×3100mm | 16100×5100×3100mm | 16100×5100×3100mm |

| Glue Type | Water soluble cold glue (hot-melt glue) | Water soluble cold glue (hot-melt glue) | Water soluble cold glue (hot-melt glue) |

| A | B | C | D | E | |

| Max. Size (mm) | 1080 | 600 | 180 | 430 | 490 |

| Min. Size (mm) | 600 | 350 | 80 | 220 | 250 |

Technological Process

ZENBO is a professional paper bag making machine manufacturer in China. We offer premium paper shopping bag making machines, paper handle bag making machines, gift bag making machines, and more.