Featured Functions

Designed on the basis of Italy technologies, the automatic paper bag making machine is a great solution for mass production of medium and top grade paper handle bags. Combining mechanical, electrical, optical and pneumatic technologies, the machine has achieved a number of proprietary technologies.

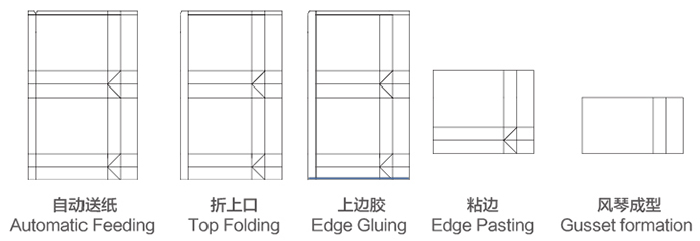

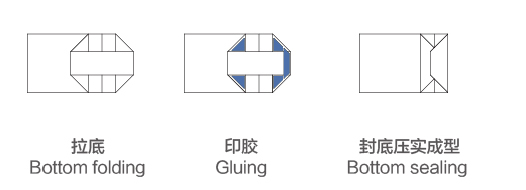

Adopting printed and die-cut paper as the raw material for bag making, the paper bag machine is able to finish all production steps at a stroke, from automatic paper feeding, positioning, top folding, tube folding, bottom folding and gluing, to final product delivery.

Due to the variable speed drive technology, vertical and horizontal creasing function, as well as automatic bottom folding function, the paper bag making machine realizes accurate and simple bag bottom forming. The utilization of PLC control and variable frequency control technologies help realize both centralized control and single-point remote control.

The automatic paper bag making machine features great bag forming performance and high production efficiency, and its technology ranks top in domestic markets.

Features

1. Due to the paper feeder supporting feeding paper from a paper stack, the automatic paper bag making machine is able to realize non-stop paper feeding, thus reducing paper loading time and improving production speed.

2. Front and side guides are available to ensure accurate position of every piece of paper.

3. The automatic paper bag making machine is designed with an automatic top folding system and gusset forming system.

4. Both water soluble cold glue and hot melt glue can be used.

5. A screw rod adjustment system is available to help shorten adjustment time and improve production efficiency when the paper bag maker is used for producing bags with different specifications.

6. The paper bag making machine alarms when the paper roll falls down.

7. Automatic collection system: the paper bag machine offers automatic counting function, which makes it convenient for bag collection.

8. Nordson hot melt adhesive system is available as a standard. It helps fasten adhesion speed, making the machine shift to the next step in the shortest period of time.

| Max. sheet size (LX W) | 1200x600mm |

| Min. sheet size (LX W) | 540x300mm |

| Paper weight | 190g-300g/m2 |

| Bottom width | 80-180mm |

| Bag width | 180-430mm |

| Total power | 15kw |

| Machine size | 16100x5100x3100mm |

| Speed | 45-55bags/min |

| Total weight | 16T |

| Glue type | Water soluble cold glue (hot-melt glue) |

The automatic paper bag making machine is compatible with Kraft paper and art paper, including paper material laminated with film. The paper material needs creasing before feeding.

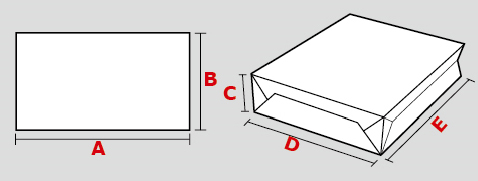

| A | B | C | D | E | |

| Max. Sheet Size | 1200 | 600 | 180 | 430 | 500 |

| Min. Sheet Size | 540 | 300 | 80 | 180 | 250 |